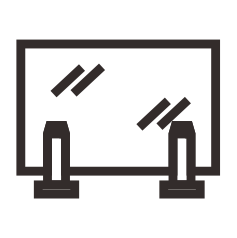

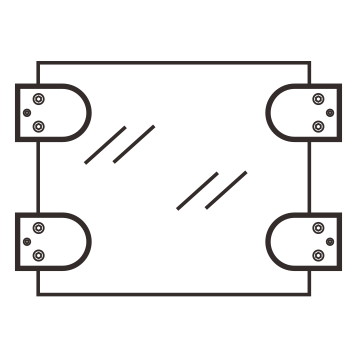

Surface Finish Polishing

Product is first grinded by sand belt to remove rough surface. Then it is polished by machines to get brushed or smooth metal surface.

After that, inspection of surface finish is done to ensure to meet quality standard which is especially important before plating or coating.

After that, inspection of surface finish is done to ensure to meet quality standard which is especially important before plating or coating.

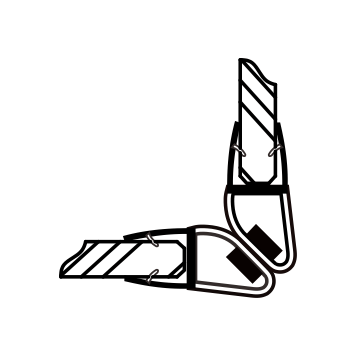

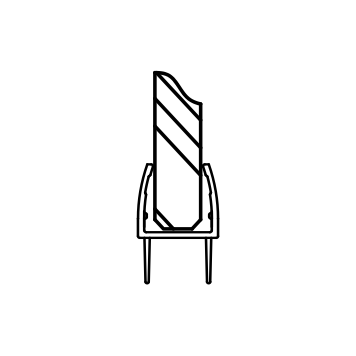

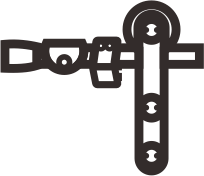

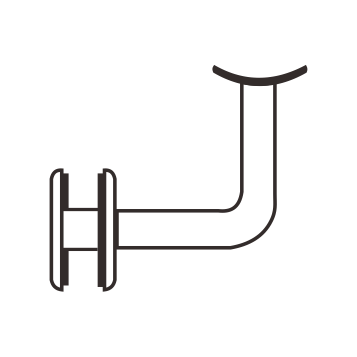

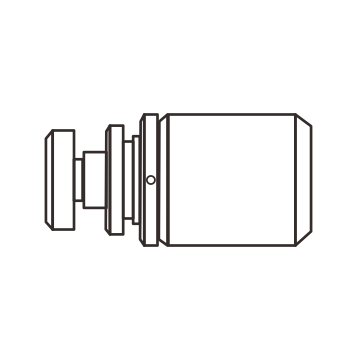

CNC Machining

It employs computerized controls and machine tools to produce a custom-designed part, which require tighter tolerances. The automated nature of CNC machining enables the production of high precision and cost-effectiveness when fulfilling volume production runs.

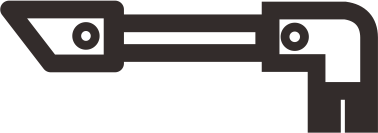

Cutting and Machining of the Extrusion

Performed by CNC machines (Drlling and milling).

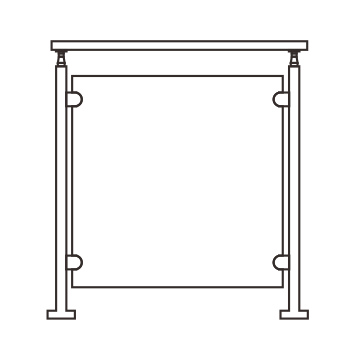

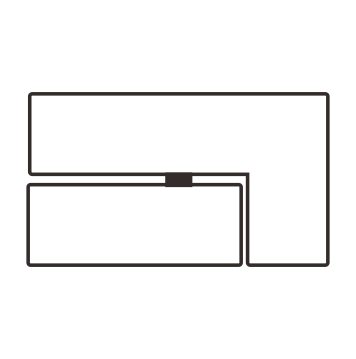

Surface Finish Polishing

Product surface is first grinded by sand belt to remove irregularities and rough. Then is polished by machines to get brushed or smooth metal surface.

After that, inspection of surface finish is done to ensure to meet quality standard which is especially important before plating or coating.

After that, inspection of surface finish is done to ensure to meet quality standard which is especially important before plating or coating.

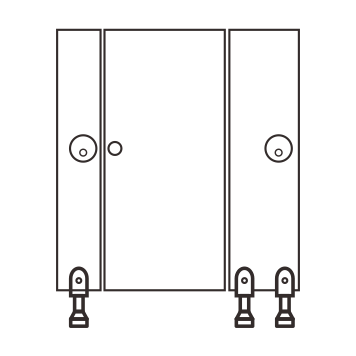

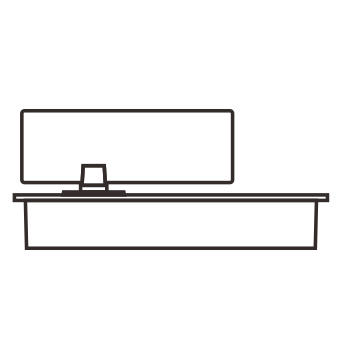

CNC Machining

It employs computerized controls and machine tools to produce a custom-designed part, which require tighter tolerances. The automated nature of CNC machining enables the production of high precision and cost-effectiveness when fulfilling volume production runs.

Cutting and Machining of the Extrusion

Performed by CNC machines (Drlling and milling).